Nowadays, many businesses are present on one or some online platforms. They place their inventory for a retail sale and receive an order and fulfill it as perfectly as possible. In this process, the business owner should keep an eye always on the items and product lists and keep control of the inventory management to avoid any unexpected consequences like a failure of order because of lack of the item.

The inventory in any type of business is one of the most valuable things; the raw materials and the final products are so important to the company. Managing inventory lets the business owner know what and how much to purchase or to produce, what price and how much to store, and also when to sell and at what price. Optimum inventory management sure would make these complex decisions much easier.

Table of Contents

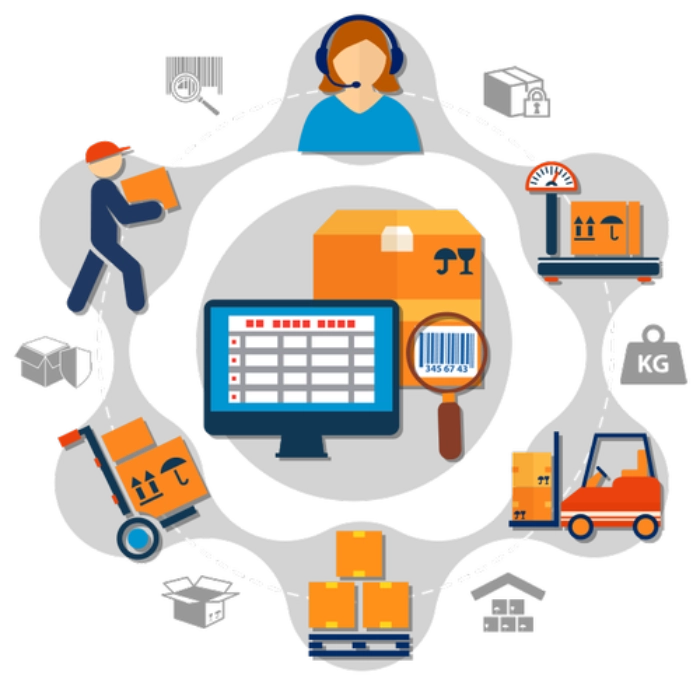

The inventory management process

what is inventory management? Inventory management includes tracking and controlling the stocks from the very first place which is the supplier to the warehouse in Vancouver and to the client. There are 5 steps in this complex process which are namely: purchasing, production, holding stock, sale, and report.

The report stage is used to figure out how much revenue is made by selling each unit and it plays an important role in inventory management systems as it determines the prospective purchase from the supplier which is the first step of the whole process.

What are Stock Control and Inventory Management?

Inventory management is all the acts for sourcing, storing, and selling the inventory. Also, stock control or inventory control refers to the tracking of real-time stock you have in your warehouse. This is the whole process of managing and controlling the inventories from raw materials to the ultimate ones or target products.

If you own an online business you should be aware of common strategies and technics to manage and control your inventory. Here in this article, we list some of the efficient ways to do this perfectly. These technics help you avoid shortages and let you plan and forecast any problem in your inventory.

Understanding the supply and demand

You should always have enough stock to sell. If you run short of stock and you are not aware of it, this may turn into trouble; it may cause a failure of the order and ruins your reputation. Market research is a key factor in supply and demand affairs.

It helps you decide what quantity of stock to store and how many to buy. Also by calculating the cost of storing, you decide how much to store and it lets you get rid of the stocks which are held in the warehouse for a long time.

Read more: Choosing the Best Logistics Provider for Your Truckload Shipments

The use of inventory management software

An efficient way to manage the inventory is to use coherent warehouse inventory management software specialized for stock control and inventory management techniques. The software can help you decide about your current stock, replenishment times, forecasts, sale, and many other determining things.

Stock in each warehouse

The company should be always aware of the stock in each warehouse at any time. This is so important in logistics affairs, as a manager may decide to replace the stock or to supply stock to keep it near the major client base.

Read more: What is delivery management in 3pl logistics?

Just-in-time (JIT) inventory

This technic is so simple. The JIT is a technic that suggests holding a few stocks of each item. Small companies don’t have enough funds to keep a great deal of stock, so they should accept the risk and cost of holding an item that may not have the expected revenue while it has the storing costs. This technic states that you should divide the risk and cost among the stocks and lets you decide the amount of stock that you purchase from the supplier later.

The bulk shipment

When you have a certain client base and based on experience you are sure about the sale of an item, the bulk shipment can augment your revenue naturally. When you purchase some goods from the supplier in bulk, you buy them cheaper and you have this opportunity to increase the revenue or to set a small discount to attract more clients.

Storing costs

The bulk shipment has its own risk. The storing costs should be calculated before any purchase as you should occupy more room for an item. If the market changes or a competitor present a better or cheaper product, you may undergo a big loss. Therefore you should have a certain data analysis and a perfect forecast about the future needs of the market and decide what to do if the market has no demand for your goods.

Days sales of inventory (DSI)

This is an index in the stock and just in time inventory management that indicates the average time needed to sell the inventory. This ratio starts from the day you purchase it from the supplier to the day you fulfill it and the customer receives it from you. A lower DSI is optimum for the business. The lower it is, the faster the company obtains revenue.

The quantity of stock to hold in the warehouse

Also, this index helps the business owner to decide the quantity of stock to hold in the warehouse. This index determines what to keep more and what to keep less. You should always consider the variety of products to present to your customers, thereby you can keep your inventory charged based on the DSI, without removing one of them just because the demand is low.

Read more: Sustainable eCommerce: How Can Brands Become More Eco-Friendly?

The Conclusion

Inventory management and stock control as explained is a professional affair and demands years of experience to have command of the whole process. If you have any questions about it or your company needs consultation about inventory management solutions, feel free to contact the Delgate group. In case you are a business owner and want to boost your stock control and make use of the recent techniques and strategies, the Delgate company provides a coherent and personalized solution for you.