These days thanks to the fast-paced world of logistics and supply chain management, efficient warehouse operations play a vital role in ensuring timely and accurate delivery of goods. One key aspect of these operations is the sorting process, facilitated by specialized sorting facilities. In this article, we will delve into what sorting facilities are and explore the importance of the warehouse sorting process.

Table of Contents

What are Sorting Facilities

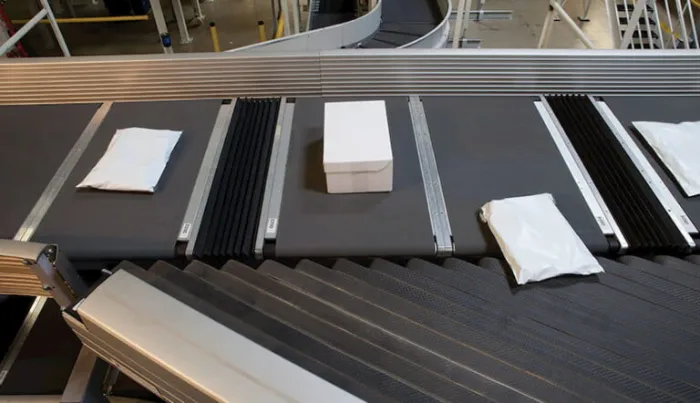

Sorting facilities, also known as sortation centers or distribution centers, are specialized hubs where incoming packages, parcels, or mail are meticulously processed and organized based on specific criteria.

These facilities serve as central hubs where items from various origins converge, enabling the efficient routing and redistribution of goods to their intended destinations. The incorporation of advanced sortation in warehouse systems within these facilities ensures a streamlined process, enhancing overall efficiency and accuracy in the sorting and distribution of items.

The Role of the Warehouse Sorting Process:

The warehouse sorting system is an important step in the supply chain, ensuring that goods are properly sorted and delivered to the destination Some basic reasons why the sorting system is so important is:

1. Enhanced Operational Efficiency: Efficient sorting processes streamline warehouse operations, improving overall efficiency. By organizing, warehouse sorting systems can reduce handling time, provide more efficient use of space, and reduce the risk in case of errors or misplacement, indirectly leading to increased efficiency and cost reduction for the industry.

2. Accurate Order Fulfillment: Packaging plays an important role in successful order fulfillment. By carefully sorting products based on specific criteria such as destination, shipping methods, and customer needs, Canada warehouse can ensure that the right products reach the right customers on time. This reduces ordering errors, increases customer satisfaction and strengthens brand reputation.

3. Expedited Delivery Times: Timing is critical in today’s competitive market. Efficient packaging allows warehouses to prioritize time-critical items and ship them faster. By streamlining packing and transportation, warehouses can dramatically reduce delivery times to meet or exceed customer expectations.

4. Optimal Inventory Management: The sorting process enables warehouses and warehouse sorting systems to maintain optimal inventory management. By categorizing and organizing items based on various attributes such as SKU, batch, or expiration date, warehouses can efficiently track and manage inventory levels. This minimizes stockouts, avoids overstocking, and enables better demand forecasting.

5. Seamless Integration with Transportation Networks: Sorting facilities act as pivotal connection points between warehouses and transportation networks. By employing advanced sortation in warehouse systems and sorting items according to their intended destinations or specific transportation requirements, warehouses can seamlessly integrate with various carriers. This optimization enhances the transportation process, ensuring swift and efficient delivery while maintaining accuracy in sorting for streamlined operations.

Read more: Canada-wide shipment Service

Inbound Sorting

Inbound sorting involves the efficient handling and sorting of goods or materials into the warehouse. Simplifying inbound sorting offers several benefits:

- Improved receipt: You can speed up the receipt process by inbound sorting and categorizing shipments more accurately. Properly labeled and organized items provide faster identification, reduce manual errors, and ensure proper inventory updates.

- Space efficiency: Organize sortation in logistics to allocate appropriate storage space based on product characteristics such as size, flexibility, or temperature requirements. This ensures safe use of warehouses and assembly areas, prevents accidents and reduces the risk of damage.

- Enhanced inventory visibility: Enables real-time visibility of inventory levels and locations according to the sequence of arrivals. By sorting specific items, you can find specific items more quickly, reducing search time and improving order processing speed.

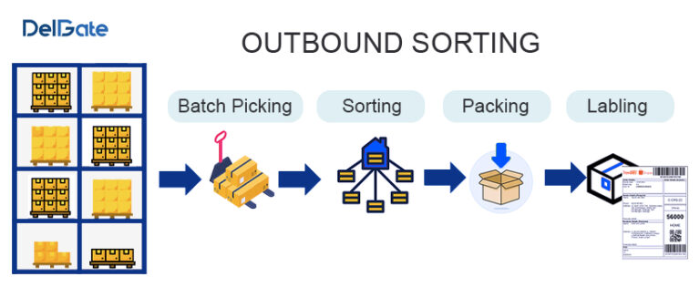

Outbound Sorting

Outbound sorting focuses on organizing and sequencing orders for efficient picking, packing, and shipping processes. Optimizing outbound sorting offers the following advantages:

- Order Accuracy and Timeliness: Effective outbound sorting ensures that the right products are picked and packed for each order. By sequencing items according to their destinations, you can streamline the picking process, minimize errors, and expedite order fulfillment, leading to enhanced customer satisfaction.

- Delivery Optimization: Sorting outbound orders by delivery route or carrier requirements facilitates smoother transportation operations. This allows for efficient load planning, accurate manifesting, and timely scheduling, reducing transportation costs and ensuring on-time deliveries.

- Reverse Logistics Handling: Outbound sorting also plays a crucial role in handling returns and reverse logistics. By categorizing returned items based on their condition, reasons for return, or restocking requirements, you can streamline the reverse sortation in logistics process, reducing processing time and enhancing customer service.

Read more: 3PL EDI for Third Party Logistics

Implementing Efficient Inbound and Outbound Sorting:

To optimize inbound and outbound sorting processes, consider the following best practices:

- Utilize Sorting Technology: Leverage advanced sorting systems, barcode scanners, and RFID technology to automate and expedite sorting processes. These technologies enhance accuracy, speed, and overall operational efficiency.

- Standardize Sorting Procedures: Establish standardized sorting procedures and train warehouse staff accordingly. Clear guidelines ensure consistency and minimize errors, regardless of the operator or shift.

- Embrace Data Integration: Seamlessly integrate your warehouse management system (WMS) with sorting equipment to enable real-time data exchange. This integration enhances visibility, reduces manual data entry, and facilitates proactive decision-making.

- Continuously Evaluate and Improve: Regularly analyze sorting performance metrics, such as throughput, accuracy, and order cycle times. Identify bottlenecks, implement process improvements, and leverage feedback from warehouse staff to enhance sorting operations.

Read more: Read more: What is a Warehouse Management System (WMS)?

OVERCOMING WAREHOUSE SORTING CHALLENGES

Overcoming warehouse infrastructure challenges is an important endeavor for businesses trying to optimize supply chain management. In today’s fast-moving market, an efficient sortation in warehouse system is essential to meet customer demands for faster order processing.

Challenges such as high order volumes, variety of orders, and the need for ordering accuracy can impede procurement efficiency. However, these challenges can be overcome with the right combination of technology, flexible workflows and well-trained personnel. implementing automated sorting systems and optimizing warehouse systems are just two options that can increase sorting capacity and ensure products reach customers on time, every time.

In the ever-evolving landscape of warehousing, sorting poses significant challenges that demand innovative solutions. To optimize your sorting processes and stay ahead of the competition, let’s explore three key challenges and effective tips for a better warehouse sorting systems process.

- Balancing Accuracy and Speed: Achieving a delicate balance between accuracy and speed is crucial in today’s fast-paced 3pl logistics world. Leverage advanced technologies, such as automated sorting systems and intelligent algorithms, to expedite sorting operations while maintaining impeccable accuracy levels. By automating repetitive tasks, you can significantly reduce errors and increase overall efficiency.

- Managing High Volume and Variety: The increasing volume and variety of items to sort require adaptable strategies. Organize your products systematically by category or type, enabling easy identification and streamlined shipping processes. Embrace the power of machine sorting to expedite operations, minimize costs, and maximize productivity. The right sorting software can provide real-time insights, monitor key metrics, and offer proactive alerts to avoid potential issues.

- Embracing Flexibility in Sorting Methods: Flexibility is key in addressing evolving market demands. Continuously evaluate your sorting strategies and explore innovative technologies that align with your unique requirements. Optimize your warehouse sorting process layout to reduce travel times and eliminate obstacles, enhancing overall efficiency. Prioritize ergonomics to create a conducive work environment that boosts employee productivity and well-being.

To achieve a flawless sorting process, ensure seamless integration between your ERP and WMS systems. This alignment enables synchronized data management, enhancing accuracy and reducing delays. Embrace a dynamic mindset, constantly evaluating and refining your sorting strategies to adapt to changing times.

Remember that there is no single solution in warehouse sorting. Embrace a flexible approach while welcoming mutation, innovation and innovation. By being nimble and embracing change, you can maintain your competitive edge and achieve success in today’s ever-evolving industry.

Unlock the potential of your warehouse sorting systems processes, revolutionizing efficiency, accuracy, and customer satisfaction. Together, let’s conquer the challenges and embrace the possibilities that lie ahead.

Read more: What Are The Benefits of Dedicated Trucking Service? Know 7 Reasons

Conclusion

Sorting facilities and the warehouse sorting process are integral components of an efficient supply chain. By investing in robust sorting infrastructure and implementing effective sorting procedures, businesses can streamline their operations, enhance order fulfillment accuracy, expedite delivery times, optimize inventory management, and seamlessly integrate with transportation networks.

Embracing the importance of sorting facilities and continually improving the warehouse sorting systems process enables businesses to stay ahead of the competition, provide exceptional customer experiences, and pave the way for success in today’s demanding marketplace.