In this article, we want to talk about Different types of Cross Docking services in Canada, Vancouver BC, Toronto ON, and Mississauga ON.

Before that, we want to discuss a little about cross-docking services.

Developing new ways to:

- Speed up delivery times

- Eliminate waste

- Making the most of your company’s existing transportation network and resources

These are central to the goals of any company with a logistics component.

Related article: What is Transloading in 3PL Logistics?

Table of Contents

What is Cross Docking?

Cross Docking is one of the key methods logisticians employ that, under the right circumstances, can streamline a company’s shipping process and avoid unnecessary delays, storage, and costs.

Essentially, Cross Docking removes the “warehousing” link from the supply chain.

Products are unloaded from a truck or rail car, sorted, and reloaded directly onto outgoing trucks or rail cars to continue their journey.

Products going to the same destination can be easily consolidated into fewer transport vehicles. As an alternative, large shipments can also be divided into smaller groups to facilitate delivery. The end result in both scenarios is a more agile and efficient supply chain.

Read more: How to perfect your Cross-docking process

- In its simplest terms, Cross Docking is a strategy that avoids the need to handle or store inventory.

Instead, inventory items are sorted and distributed as requested (instead of being stored in bulk) and staged for shipment directly to users or retailers, without products being held in a warehouse location for future distribution.

This process occurs within a distribution terminal, a facility divided between entry and exit docks with minimal storage space between them.

The physical process of moving goods from the inbound docks directly through these terminals to their outbound destinations gives Cross Docking its name.

Related article: What Does Cross-Docking Mean in Logistics? Know Benefit & Usage

Different types of Cross Docking services

Today, many e-commerce players are switching from the traditional distribution management model to a cross-docking approach. There are two main types of Cross Docking services: pre-distribution and post-distribution.

Pre-distribution Cross Docking

If warehouse personnel know the end customer even before the supplier ships the products, as soon as the shipment arrives at the dock, it is unloaded, sorted, and repacked according to pre-agreed distribution instructions.

In this pre-distribution type of Cross Docking service, inventory spends very little time in the cross-docking warehouse.

It is best suited for retailers who run their own warehouses and have direct insight into all of their own customer and supplier relationships.

Post-distribution cross-docking

With the post-distribution process, goods are stored in the Cross Docking facility until the next leg of the journey is cleared, meaning demand is mapped and customers are identified.

This type of service would result in the inventory remaining in the Cross Docking warehouse for a slightly longer period of time.

But on the other hand, distributors and retailers can take the time to strategically decide which location to ship inventory to base on forecast inventory numbers and current inventory counts.

Common Cross Docking Methods

The specific strategies recommended for your business depend entirely on the products being shipped.

These are the most common variants of Cross Docking procedures:

Cross Docking for Retailers or Distributors: This is the basic method of Cross Docking, used to efficiently organize and consolidate incoming products from different vendors into units for distribution among multiple retail locations.

Manufacturing Cross Docking: This is self-explanatory and applies to order-specific products received by a distribution center to be assembled or configured prior to shipment to a manufacturing location.

Transportation Cross Docking: As smaller shipments (including shipments less than a full truckload) arrive at a distribution terminal, they can be combined into one larger shipment to save on transportation.

Cross-docking hub-and-spoke: This is a general term for when goods are received at a central location and then sorted for delivery to a variety of destinations.

Opportunistic Cross Docking: This is more of a case-by-case method of transportation, describing the transfer of products directly to an outbound shipping dock to fulfill a customer’s sales order.

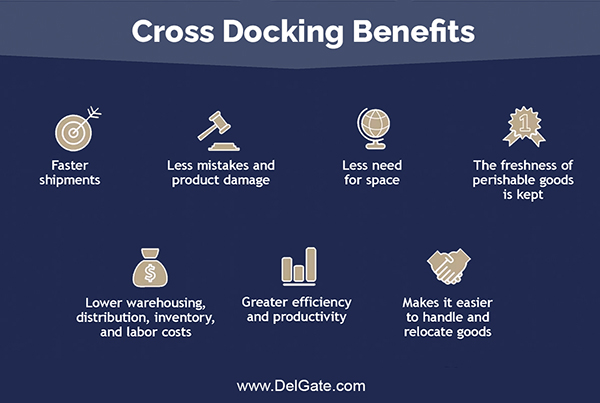

Key Advantages of Cross Docking Services

In general, there are several main benefits to incorporating Cross Docking into your retail supply chain. Because products spend less (or no) time in the warehouse, inventory carrying and storage costs are greatly reduced.

Here are some key benefits of types of Cross Docking services:

Reduce Facility Footprint: With the use of Cross-docking, businesses can easily reduce the total square footage required in a facility. Since the process requires little or no storage, businesses need less space. This, in turn, reduces the costs associated with inventory storage.

Less Material Handling: Companies can also see visible reductions in material handling costs. When companies opt for Cross-dock, the material handling process is limited to just the loading and unloading of goods, with minimal picking or preparation activities.

Improve Product Quality: Cross-docking also helps improve product quality. When products are unloaded and staged, staff can manually inspect the merchandise for damage. This reduces the total amount of damaged products that are delivered to customers and, in turn, helps increase customer satisfaction.

Labor cost savings: As material costs are greatly reduced, this directly impacts labor costs. As labor costs are reduced, the savings can be passed on to customers. In this way, Cross Docking can help a business gain a competitive advantage through cost.

Less Damage: As Cross Docking involves minimal handling, products remain damage-free. This again reduces the costs involved in damaged inventory.

Reduced delivery times: Cross Docking also helps with the reduction of the total delivery time. Cross-docking companies that offer cross-docking services are usually located close to the final delivery destination. Because of this, there is no excess travel and final deliveries are made as soon as possible.

Reduced Transportation Costs: Cross Docking also helps reduce transportation service costs. As the routes are well optimized, travel involves fewer miles and this reduces vehicle service and fuel costs.

Related article: 10 Most Commonly Asked Freight Shipping Questions In Logistics – Canada

Conclusion

Cross Docking may not be suitable for every business or warehouse. It is important to consider both the pros and cons of the process before making a decision. Cross-docking companies or warehouses need to analyze whether cross-docking can help:

- improve product quality

- reduce costs

- increase customer satisfaction.

By understanding the process and different types of Cross Docking services, a business can make an informed decision about using it. Be sure to contact your warehouse manager with any questions you may have.