Solid inventory control is the secret to a company’s lasting success. It’s not just about keeping track of what you have; it’s about strategically managing your stock to stay ahead in the competitive market. One game-changer in this arena is the use of inventory management tools. These handy resources don’t just streamline processes—they also cut costs and maximize storage space, leading to quicker shipping times and happier customers.

Today, businesses are waking up to the significance of these tools as part of their broader strategy. Imagine having the ability to improve your supply chain management, swiftly prevent stockouts or overstocking, and be nimble enough to meet changing customer demands. Integrating inventory management strategies can enhance your operations and make your fulfillment services Canada more efficient. Using inventory management tools can result in notable cost savings and improved cash flow management, which is something every business owner can appreciate.

Table of Contents

The Role of Inventory Management in Logistics

When it comes to logistics, inventory management is a key player. This is especially true in places like Canada, where there’s a growing demand for third-party logistics (3PL) services. Think about it—fulfillment services, public warehouses, and 3PL warehouse services are all intertwined in a complicated web of supply chain management. By employing inventory management tools, businesses can enhance their logistics processes and become more adept at catering to customer needs.

Let’s take a look at some eye-opening statistics about stock control in logistics:

| Metric | Value |

| Average annual inventory value | $1.4 billion |

| Average inventory turnover | 6.9 times per year |

| Average stockout cost | $1.3 million per day |

| Average inventory management cost | 10% of total inventory value |

Examples of Inventory Management Tools

The great news is there’s a treasure trove of inventory management tools available, each with its own set of unique features. Some of the most popular include:

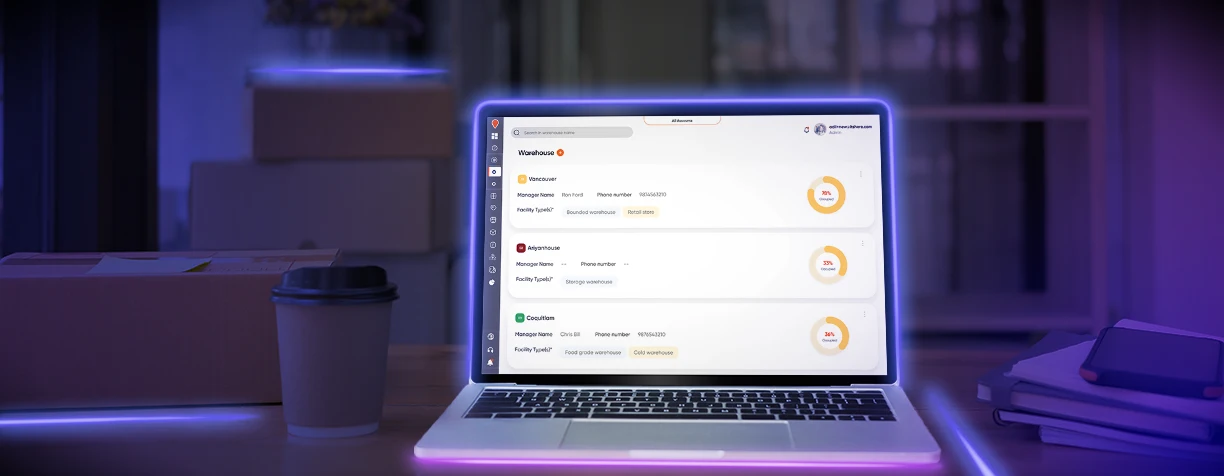

- Inventory Management Software: Picture a tool that automatically updates when stock changes. It is like having a super-smart inventory butler, always keeping things in sync.

- Warehouse Management Systems (WMS): These systems take inventory tracking and order fulfillment to the next level through automation.

- Enterprise Resource Planning (ERP) Systems: Imagine one platform that integrates all your operations, bringing clarity and cohesion to your supply chain.

- Radio Frequency Identification (RFID) Tags: These little gadgets can help track inventory with precision, almost like a GPS for your products!

- Automated Data Collection Systems: Real-time tracking? Yes, please! These systems make data collection effortless and accurate.

Here’s a quick overview of what these tools can do for you:

| Tool | Benefits |

| Inventory Management Software | Boosts accuracy, slashes costs, and enhances reporting capabilities. |

| WMS | Offers automated tracking, optimizes space, and improves order accuracy. |

| ERP Systems | Delivers integrated management and better visibility across the supply chain. |

| RFID Tags | Increases accuracy, reduces manual labor, and improves asset tracking. |

| Automated Data Collection Systems | Enables real-time tracking with high data accuracy and valuable insights. |

Benefits of Using Inventory Management Software

With inventory management tools, businesses can really elevate their inventory management game. Here are some standout benefits:

- Improved Accuracy: No more guesswork—your numbers are right on target.

- Cost Reduction: By optimizing stock levels, you’ll notice a decrease in holding costs.

- Enhanced Reporting: Dive deep into data and make informed decisions quickly.

Benefits of Using Warehouse Management Systems (WMS)

WMS is not just any inventory management tools; it’s a critical resource that empowers businesses to effectively manage their warehouse operations. Imagine being able to track inventory levels live, improve space utilization, and ensure accurate order fulfillment—sounds ideal, right?

Here’s a relatable story: A mid-sized company implemented a WMS and saw its order fulfillment accuracy soar to new heights, cutting down on errors and improving customer satisfaction.

Benefits of Using 3PL Warehouse Services in Canada

Now, let’s talk about the perks of utilizing 3PL warehouse services to manage inventory levels and meet customer demands. Here’s a breakdown of how businesses benefit from 3PL warehouse services:

| Service | Benefits |

| 3PL Warehouses in Vancouver | Enhanced inventory management and better order fulfillment. |

| 3PL Warehouses in Kelowna | Lower management costs, increased accuracy. |

| 3PL Warehouses in Toronto | Greater visibility and improved decision-making. |

Benefits of Using ERP Systems

ERP systems are fantastic for managing supply chain operations. They offer real-time tracking, better space utilization, and order accuracy that can transform your operations. Additionally, integrating inventory management tools within your ERP can further enhance your ability to oversee stock levels and streamline processes. Companies that use ERP see a notable uptick in operational efficiency—just ask anyone who’s made the switch!

Restaurant Inventory Management Best Practices

Consider a bustling restaurant chain in Toronto. They struggled with inventory levels and customer demand, leading to chaotic scenes during busy hours. After switching to an inventory management system and utilizing 3PL services in Kelowna, they managed to cut their inventory costs by 20% and boost order accuracy by 30%. Talk about a turnaround!

Benefits of Using RFID Tags

RFID tags are a brilliant way to keep tabs on inventory levels in real-time. The best part? They can help minimize manual labor while ensuring your products are accurately tracked. Here’s a quick look at what they offer:

| Tool | Benefits |

| RFID Tags | Boost inventory accuracy, decrease manual tasks, and improve tracking. |

Benefits of Using Automated Data Collection Systems

Automated data collection systems are a game-changer, enabling businesses to track their inventory smoothly and effortlessly. Imagine getting insights at your fingertips without all the manual labor—it’s possible! One great example is an all-in-one inventory management tool that helped a large retailer simplify their data collection process and reduce errors. By automating the tracking of stock levels and movements, they gained a better understanding of their inventory at all times, making informed decisions and staying ahead of the competition.

Benefits of Using Inventory Management Techniques

Businesses can also optimize inventory through various oversight techniques. Just consider some of the ways they can streamline operations:

- ABC Analysis: Classifies inventory for better management.

- Cycle Counting: Regular checks to ensure accuracy.

- Inventory Organization Reporting: Enhances visibility across your inventory.

- Vendor-Managed Inventory (VMI): Collaborates closely with suppliers for smoother operations.

Check out the key benefits of these techniques:

| Technique | Benefits |

| ABC Analysis | Improves classification and decision-making. |

| Cycle Counting | Enhances accuracy and reduces manual effort. |

| Inventory Management Reporting | Provides insights for informed choices. |

| VMI | Strengthens supplier relationships and enhances management. |

Benefits of Implementing a 3PL Logistics Strategy

Implementing a 3PL logistics strategy can significantly streamline your operations. You’ll enjoy:

- Improved Stock Control: Better management of inventory levels keeps everything running smoothly.

- Reduced Logistics Costs: Save money while improving efficiency.

- Enhanced Supply Chain Visibility: Stay informed and make savvy decisions.

Why Inventory Management is Important

Inventory management is not just a back-office task; it’s essential for survival in today’s competitive landscape. With the right inventory management tools and strategies, you can optimize supply chain management, avoid stockouts and overstocking, and stay agile in fulfilling customer needs. These tools not only streamline your operations but also provide valuable insights that help you make informed decisions to stay ahead of the competition.

Here’s a brief snapshot of the benefits of great inventory management:

| Metric | Value |

| Average Annual Inventory Value | $1.4 billion |

| Average Inventory Turnover | 6.9 times per year |

| Average Stockout Cost | $1.3 million per day |

| Average Inventory Control Cost | 10% of total inventory value |

Conclusion

In a nutshell, leveraging 3PL logistics in Canada can massively improve your operational efficiency and customer satisfaction. By partnering with a reliable third-party logistics provider for 3PL fulfillment, you can streamline your supply chain processes, slash overhead costs, and focus on what really matters—your core business. With effective 3PL strategies, your business stands to gain from better inventory management, faster delivery times, and even the fastest shipping in Canada. Ultimately, this positions you to meet customer demands efficiently and sets you up for sustainable growth and success.

.