In today’s fast-paced and highly competitive marketplace, inventory management methods are more crucial than ever for businesses striving to optimize operations, reduce costs, and enhance customer satisfaction. Whether you’re a small enterprise or a large corporation, understanding and effectively implementing various inventory management methods can dramatically influence your supply chain efficiency, profitability, and ability to scale.

This extensive guide delves into the core inventory management methods, explores the latest technological innovations, and demonstrates how partnering with fulfillment services in Canada or a top 3PL in Canada can help you streamline your inventory processes. We will examine key strategies such as ABC analysis, JIT, RFID, lean inventory management, forecasting techniques, and more, with a focus on leveraging inventory management software, fulfillment center Vancouver, and regional warehouses like Kelowna to achieve the fastest shipping times and superior service levels.

Table of Contents

Understanding the Foundations of Inventory Management

What is Inventory Management?

What is inventory management? It is the systematic process of ordering, storing, tracking, and controlling a company’s stock of raw materials, work-in-progress, and finished goods. Proper inventory control methods ensure that you have the right products available at the right time, minimizing excess inventory and stockouts. Effective management directly impacts operational costs, cash flow, and customer experience.

Why is Inventory Management Important?

In an era where customer expectations are higher than ever for fast, reliable delivery, inventory management plays a pivotal role. Streamlined inventory management techniques help minimize unnecessary waste, enhance cash flow, and allow companies to adapt swiftly to changing market needs. The integration of inventory management solutions like software, RFID, and dashboards allows for real-time visibility and precise control over stock levels.

Industry-Specific Needs

Different industries require tailored inventory control methods:

- Retail: Quick turnover, multi-channel sales, and high customer expectations.

- Manufacturing: Just-in-time (JIT) inventory to minimize storage costs and ensure component availability.

- Healthcare: Strict compliance and traceability, often requiring RFID or barcode systems.

- E-commerce: Fast shipping, order accuracy, and scalability.

Choosing the right inventory management solutions depends heavily on your industry, product mix, and business size.

Key Inventory Management Methods

1. ABC analysis in inventory management

ABC analysis is a classification technique that segments inventory into three categories based on their value and importance:

- A-items: High-value, low-quantity products that require tight control and frequent review.

- B-items: Moderate value and quantity, necessitating regular monitoring.

- C-items: Low-value, high-quantity items managed with simplified controls.

Implementing ABC analysis allows businesses to allocate resources effectively, focusing attention on high-impact A-items while simplifying management of C-items. Integrating this method with inventory management dashboards provides real-time insights and enables dynamic adjustment of stock levels.

2. just in time inventory management

Just-in-time (JIT) is a lean inventory management method that minimizes stockpiling by synchronizing procurement and production with customer demand. JIT reduces storage costs, waste, and excess inventory, but it demands precise forecasting, reliable suppliers, and streamlined logistics—making fulfillment services in Canada particularly valuable for timely replenishment.

3. RFID Inventory Management

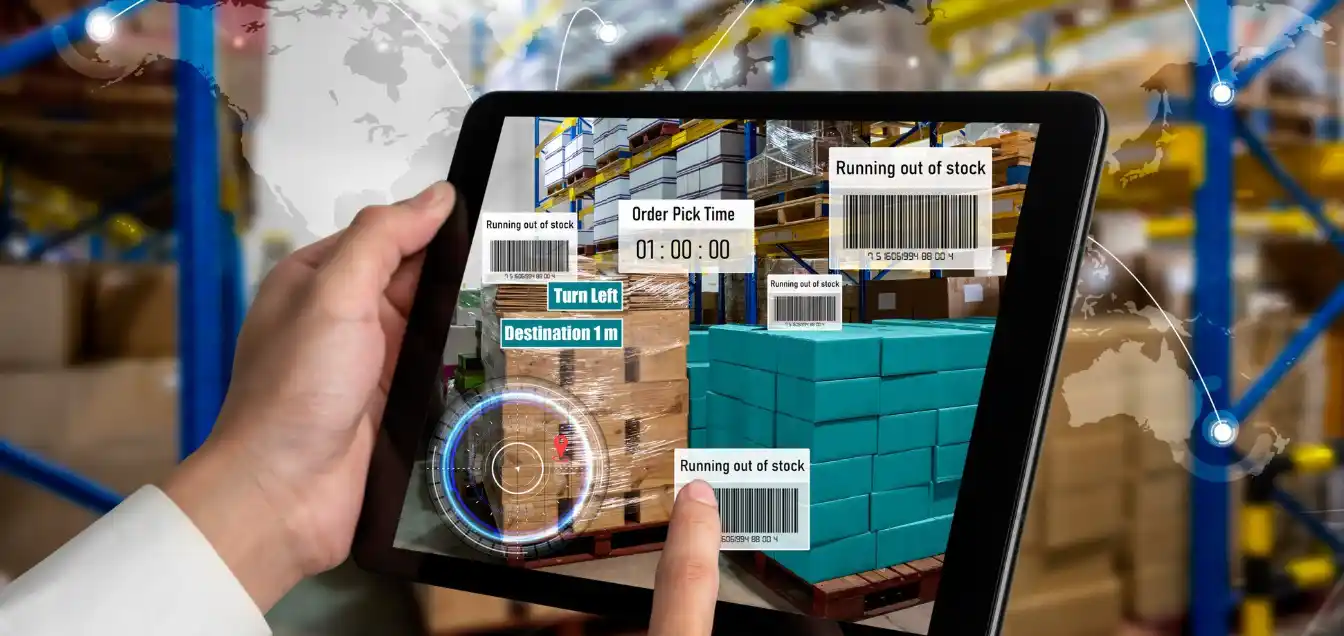

Using radio-frequency identification (RFID) tags for inventory management enables automated tracking of stock items, significantly boosting precision and reducing manual effort. RFID technology allows real-time visibility into inventory movements, drastically reducing manual counting errors and increasing stock accuracy—especially vital in 3PL warehouses Canada, Kelowna, or Toronto where high-volume stock management is commonplace.

4. Lean Inventory Management

Lean inventory management emphasizes eliminating waste and streamlining operational processes. It advocates maintaining only the minimum stock needed to meet customer demand, encouraging continuous improvement and flexibility. This approach aligns well with industry-focused inventory management strategies, making operations more responsive and cost-effective.

5. Forecasting Techniques in Inventory Management

Precise forecasting methods are crucial for determining the ideal inventory quantities needed to meet demand effectively. Methods such as moving averages, exponential smoothing, seasonal adjustments, and machine learning models analyze historical data to predict future demand. Proper forecasting reduces stockouts, overstocking, and helps plan for seasonal fluctuations, enabling smarter inventory control methods.

Implementing Inventory Management Methods Across Canada

Partnering with Fulfillment Services in Canada

Partnering with fulfillment services in Canada like DelGate unlocks access to advanced inventory management methods and infrastructure without heavy capital investment. These providers offer scalable, flexible solutions, including 3PL warehouse in Kelowna, integrated inventory management software, and logistics support, in key regions such as Vancouver, Toronto, and Kelowna.

The Strategic Importance of 3PL in Canada and Warehousing Locations

Choosing the right 3PL warehouse Vancouver, 3PL warehouse Toronto, or Kelowna allows your business to optimize inventory control methods by reducing transit times, lowering shipping costs, and enabling rapid order fulfillment. These warehouses utilize sophisticated inventory management solutions that provide real-time data, automation, and analytics, essential for maintaining high service levels.

The Role of 3rd Party Fulfillment Solutions

A comprehensive 3rd party fulfillment solution manages inventory storage, order processing, and last-mile delivery—often integrated seamlessly with your e-commerce platform. This integration improves inventory management methods by providing centralized dashboards, analytics, and automation features that help you make data-driven decisions.

Achieving the Fastest Shipping in Canada

Efficient inventory control methods directly impact your ability to offer the fastest shipping in Canada. By maintaining accurate stock levels, utilizing regional warehouses like Kelowna, Vancouver, and Toronto, and automating order processing, businesses can deliver within 1-2 days in major cities. Partnering with top 3PL providers ensures reliable, rapid delivery.

The Significance of Regional Warehousing

Having 3PL warehouses in Vancouver, Kelowna, and Toronto supports local inventory management, reduces transit times, and lowers shipping costs. Regional warehousing enables businesses to respond quickly to regional demand fluctuations and improves inventory management methods by providing localized control and visibility.

Leveraging Technology to Enhance Inventory Management Methods

1. Inventory Management Dashboards

An inventory management dashboard offers a centralized view of stock levels, sales trends, order statuses, and demand forecasts. It empowers managers to implement industry-focused inventory management efficiently, enabling quick adjustments and proactive issue resolution.

2. Specialized Inventory Management Software

Industry-specific inventory management software provides tailored features like batch tracking, serial number management, multi-channel integration, and compliance modules. These tools help optimize inventory control methods for retail, manufacturing, healthcare, or logistics.

3. RFID and Barcode Technologies

Implementing RFID inventory management and barcode scanning improves inventory accuracy, speeds up stock counts, and reduces manual errors. These technologies are especially useful in large warehouses and support lean inventory management practices.

4. AI and IoT Innovations

Emerging technologies like AI-driven forecasting, IoT sensors, and blockchain are poised to revolutionize inventory management methods by providing predictive insights, real-time tracking, and increased transparency. Investing in these technologies prepares your business for future growth and resilience.

Case Study: Elevating E-Commerce Logistics with DelGate

A leading e-commerce retailer specializing in consumer electronics partnered with DelGate to optimize their inventory control methods. They implemented ABC analysis to prioritize high-value SKUs, integrated RFID systems for real-time tracking, and adopted advanced forecasting models.

Results:

- 30% reduction in stock errors

- 25% faster order fulfillment

- Improved customer satisfaction through rapid, accurate deliveries

- Enhanced inventory visibility via dashboard tools

This case highlights the importance of combining inventory management solutions, regional warehousing, and strategic inventory management methods to achieve operational excellence.

Future Trends in Inventory Management Methods

The field of inventory management is constantly changing and advancing at a swift pace.

- AI and machine learning for predictive demand planning

- IoT sensors for real-time inventory tracking

- Blockchain for transparent supply chain management

- Automated warehousing robots and drones

- Cloud-based inventory management software for scalability and accessibility

Investing in these innovations can give your business a competitive edge, improve accuracy, reduce costs, and enhance the customer experience.

Summary of Key Data and Insights

| Aspect | Data / Insight |

| Average inventory turnover | 6-8 times per year (industry average) |

| Cost reduction with JIT | Up to 20% decrease in storage costs |

| RFID accuracy improvement | Up to 98% accuracy in stock counts |

| Leading 3PL in Canada | DelGate, with warehouses in Vancouver, Toronto, Kelowna |

| Fastest shipping times | 1-2 days in major Canadian cities |

| Impact of forecasting | Reduce stockouts by 15-20%, improve demand accuracy |

Final Thoughts

Mastering inventory control methods is the cornerstone of a resilient, efficient, and profitable supply chain. By adopting techniques like ABC analysis, JIT, RFID, and lean management, and integrating them with advanced inventory management software, your business can achieve unprecedented operational excellence. Partnering with a reputable 3PL in Canada like DelGate, utilizing regional fulfillment center Vancouver and warehouses in Kelowna and Toronto, will further enhance your ability to provide fastest shipping in Canada and deliver exceptional customer service.

Monitor developing innovations like artificial intelligence, the Internet of Things, and blockchain to maintain a competitive edge in industry developments. Continuous improvement and innovation in your inventory control methods will ensure you remain competitive in an ever-evolving marketplace.