Inventory management plays a vital role in the overall operational strategy of any business. As companies face increasing competition and rising customer expectations, understanding how to implement effective forecasting techniques in inventory management becomes indispensable. Accurate inventory forecasting enables organizations to maintain optimal stock levels, reduce carrying costs, meet customer demand, and enhance profitability. In this blog, we delve into ten essential forecasting techniques in inventory management that can drive your business to greater efficiency and success.

Table of Contents

Understanding Inventory Forecasting

At its core, inventory forecasting is the process of using historical sales data, market trends, and various analytics to predict future inventory demands. This prediction can significantly influence how a business manages its stock—ensuring they have the right products at the right time. As businesses strive to provide top-notch customer service, implementing reliable forecasting techniques in inventory management is paramount.

To appreciate the importance of forecasting, consider that a 2021 study from the National Retail Federation reported that U.S. retailers lose over $100 billion annually due to out-of-stock conditions. To combat this significant challenge, businesses must adopt effective inventory forecasting methods that align with their specific needs, particularly leveraging advanced Forecasting Techniques in Inventory Management strategies to minimize stockouts and maximize inventory efficiency.

1. Historical Sales Analysis

One of the foundational forecasting techniques in inventory management is historical sales analysis. This method involves evaluating past sales data to make informed predictions about future demands. By identifying patterns in customer buying behavior, businesses can forecast how much of a product they will need.

For example, let’s say a retail store sold 1,200 units of a particular product last winter season. Using historical sales data, the store can anticipate a similar demand in the upcoming winter season, adjusting slightly for any expected growth or decline. This approach not only helps in inventory planning but also enhances customer satisfaction by minimizing stockouts.

2. Moving Average

The moving average forecasting technique in inventory management smooths out fluctuations in sales data over a defined period. By looking at data from several months or years, businesses can develop a more stable and accurate forecast. This method is particularly beneficial for industries with consistent sales patterns, as it reduces the impact of short-term spikes or drops.

For example, a business might calculate a six-month moving average to forecast sales for the next month. If the previous six months showed sales of 120, 110, 130, 125, 140, and 150 units, the moving average would be (120+110+130+125+140+150)/6 = 128.33 units. This stable figure allows businesses to make informed reordering decisions, improving their inventory levels.

3. Trend Analysis

Trend analysis is a more nuanced forecasting technique in inventory management that focuses on understanding long-term movements in sales data. By identifying whether sales are increasing, decreasing, or remaining stable over time, businesses can adapt their inventory strategies accordingly. This technique often involves graphical representations, such as line charts, to visualize trends and inform decision-making.

For instance, if a toy retailer notices a gradual increase in sales during the holiday season over several years, they can adjust their inventory strategies to stock more toys well in advance.

4. Just In Time Inventory Management

Just in time inventory management is a powerful technique that aligns raw material orders with production schedules. By receiving materials only when they are needed in the production process, businesses can minimize inventory holding costs and reduce waste. This approach is particularly effective in industries where storage costs are high or when dealing with perishable items.

For example, a car manufacturer might synchronize deliveries from parts suppliers with its manufacturing schedule. By doing so, the manufacturer can minimize excess stock and ensure that parts arrive exactly when required on the assembly line, thus optimizing the production process.

5. ABC Analysis in Inventory Management

ABC Analysis is a prioritization forecasting technique in inventory management that categorizes inventory into three classes: A (high-value items), B (moderate-value items), and C (low-value items). By focusing on the A category, businesses can ensure they are always in stock on critical items that generate significant revenue.

For instance, a supermarket may identify that the top 20% of its products (Class A) account for 80% of total sales. By ensuring that these high-demand products are always available, the supermarket can reduce lost sales opportunities and improve overall customer satisfaction.

6. Time Series Forecasting

Time series forecasting, a key component of Forecasting Techniques in Inventory Management, uses historical data to predict future performance by identifying long-term patterns and seasonal variations. This technique analyzes past sales data to forecast future demands effectively. Businesses often use statistical software to build robust models that incorporate time series forecasting.

For instance, a fashion retailer might analyze sales trends over several seasons to forecast which clothing lines will be in high demand in the upcoming season, enabling them to adjust their purchasing strategy.

7. Qualitative Forecasting

Qualitative forecasting techniques, an important aspect of Forecasting Techniques in Inventory Management, rely on subjective judgment rather than quantitative data. This approach can be particularly useful for new products, market changes, or seasons with fluctuating demands. Techniques include expert opinions, market research, and focus groups. This method can be particularly effective when historical data is scarce or not available.

For example, a startup launching a new product may gather feedback from focus groups to gauge potential demand and adjust their inventory orders accordingly.

8. RFID Inventory Management

Radio Frequency Identification (RFID) technology is increasingly being integrated into inventory management methods and systems to enhance forecasting accuracy. RFID tags allow businesses to track inventory in real-time, minimizing errors related to manual tracking and stock counts. This technology is pivotal in reducing overstocks and stockouts.

A case study showed that a retail chain implementing RFID technology saw a 30% reduction in inventory discrepancies. This improvement led to more accurate forecasting and enhanced service levels.

9. Lean Inventory Management

Lean inventory management, an essential component of Forecasting Techniques in Inventory Management, focuses on optimizing efficiency while reducing waste. By adopting efficient processes that eliminate excess stock, businesses can improve operational efficiency and enhance forecasting accuracy. Lean techniques often emphasize continuous improvement and customer value.

For instance, a clothing manufacturer might streamline its production process to minimize the time between ordering materials and delivering finished products, thus refining its inventory forecasts and reducing lead times.

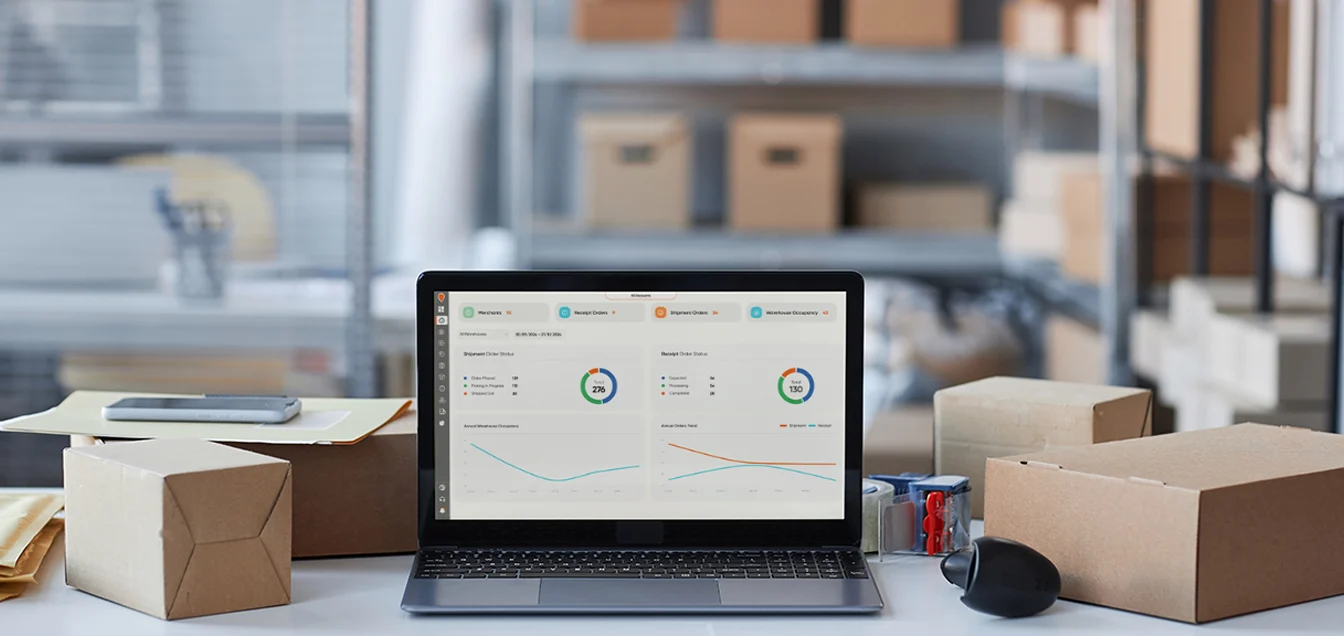

10. Inventory Management Dashboard

An inventory management dashboard provides a centralized view of key inventory metrics. With this tool, businesses can monitor key performance indicators that impact inventory levels and order management. These dashboards facilitate quick decision-making based on real-time data.

For example, an e-commerce company might use a dashboard to track inventory turnover rates and restock thresholds, optimizing their inventory levels based on current demand trends.

Supporting Data with Case Studies

To further emphasize the necessity of these forecasting techniques in inventory management from a fulfillment center in Vancouver, consider leveraging a 3rd party fulfillment solution that utilizes advanced inventory management methodologies, such as combining historical sales analysis with trend forecasting. The table below presents the implementation of various forecasting techniques in inventory management and the resulting improvements in inventory management performance.

| Technique | Implementation | Results |

| Historical Sales Analysis | 12-month data | 20% reduction in stockouts |

| Moving Average | 6-month average | Improved order accuracy by 30% |

| Just-In-Time Management | Supplier synchronization | 15% decrease in holding costs |

| ABC Analysis | Prioritization | 25% focused stock management on A items |

| RFID Technology | Real-time tracking | 40% improvement in inventory accuracy |

| Time Series Forecasting | Sales & seasonal data analysis | 35% reduction in excess inventory |

| Lean Inventory Management | Streamlined processes | 20% reduction in operational costs |

| Inventory Management Dashboard | Centralized metrics | 30% quicker decision-making |

Real Companies Offering Fulfillment Services in Canada

Several companies in Canada provide robust fulfillment services, often utilizing advanced forecasting techniques to optimize their operations. They include:

- Amazon Fulfillment: Known for its extensive networks and quick fulfillment processes.

- ShipBob: A technology-driven fulfillment company that simplifies logistics for e-commerce businesses.

- DelGate: A third-party logistics provider that focuses on efficient fulfillment and shipping solutions tailored for various business needs.

- Canada Post: The national postal service offers comprehensive fulfillment solutions across the country.

- Fulfillment by Amazon (FBA): A service that enables sellers to store their products in Amazon’s warehouses.

These providers leverage various methodologies using a 3PL warehouse in Kelowna, 3PL Warehouse Toronto, 3PL warehouse Canada, or 3PL in Canada to ensure businesses receive the fastest shipping in Canada while maintaining optimal inventory levels.

Conclusion

Incorporating effective forecasting techniques in inventory management is crucial for contemporary businesses. These strategies provide a roadmap to achieving not just inventory accuracy but enhanced customer satisfaction and overall operational success. From just-in-time inventory management to advanced technology like RFID, each technique offers unique advantages. By selecting and implementing the appropriate forecasting techniques in inventory management, businesses can maintain better control over stock levels, ultimately achieving greater success in their respective markets.

For more comprehensive resources on inventory management techniques, check out Investopedia.