In today’s rapidly evolving market, operational efficiency’s significance is more critical than ever. Businesses continuously face the challenge of improving their logistics and supply chain processes. One significant way to achieve this is by adopting cutting-edge fulfillment technology. This technology is the backbone of modern logistics, making it essential for businesses to adapt to consumer demands and rising competition. Integrating these innovative technologies can accelerate order processing, streamline inventory management, and elevate customer satisfaction.

Table of Contents

Understanding Cutting-Edge Fulfillment Technology

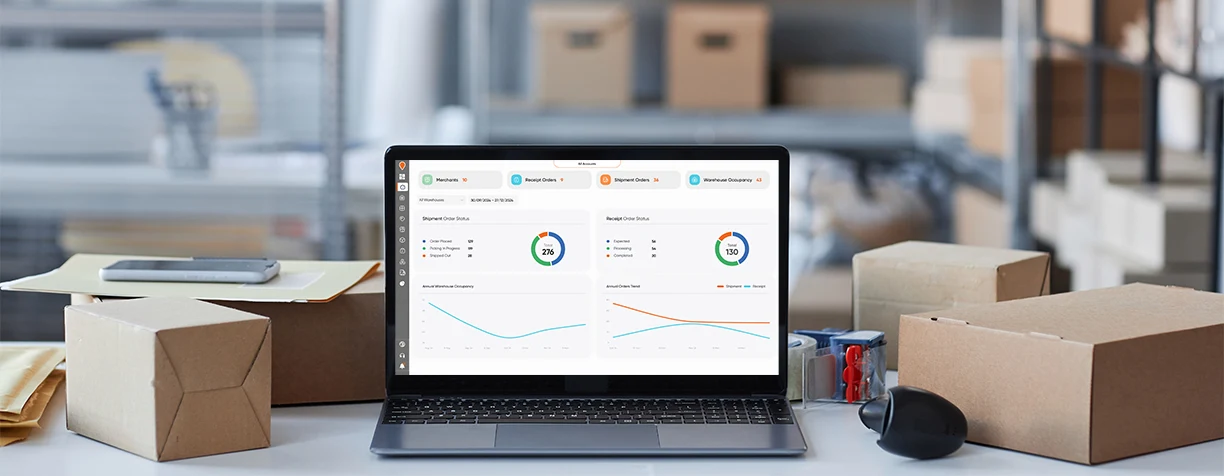

Cutting-edge fulfillment technology is not merely a buzzword; it encompasses the tools and solutions specifically designed to optimize fulfillment and logistics operations. These technologies enable businesses to manage their supply chains more effectively, ensuring faster and more accurate delivery of products. By leveraging real-time data insights, businesses can make informed decisions that enhance their overall efficiency. For example, a notable trend in the industry is the utilization of cutting-edge fulfillment technology to automate routine tasks, ranging from managing inventory levels to efficiently packing orders. Organizations that have successfully integrated these technologies into their operations report improvements in both accuracy and efficiency.

Advanced Fulfillment Solutions

One essential aspect of state-of-the-art fulfillment technology is the deployment of innovative fulfillment systems. These systems empower businesses to manage their inventory with heightened precision. For instance, implementing an advanced inventory management system can help reduce excess stock and mitigate the risk of stock shortages. A real-world example can be seen in a Canadian retail company that adopted these innovative fulfillment systems and experienced a 25% decrease in carrying costs. By utilizing sophisticated algorithms to predict demand, they effectively maintained optimal stock levels while avoiding unnecessary expenditures.

High-Tech Fulfillment Solutions

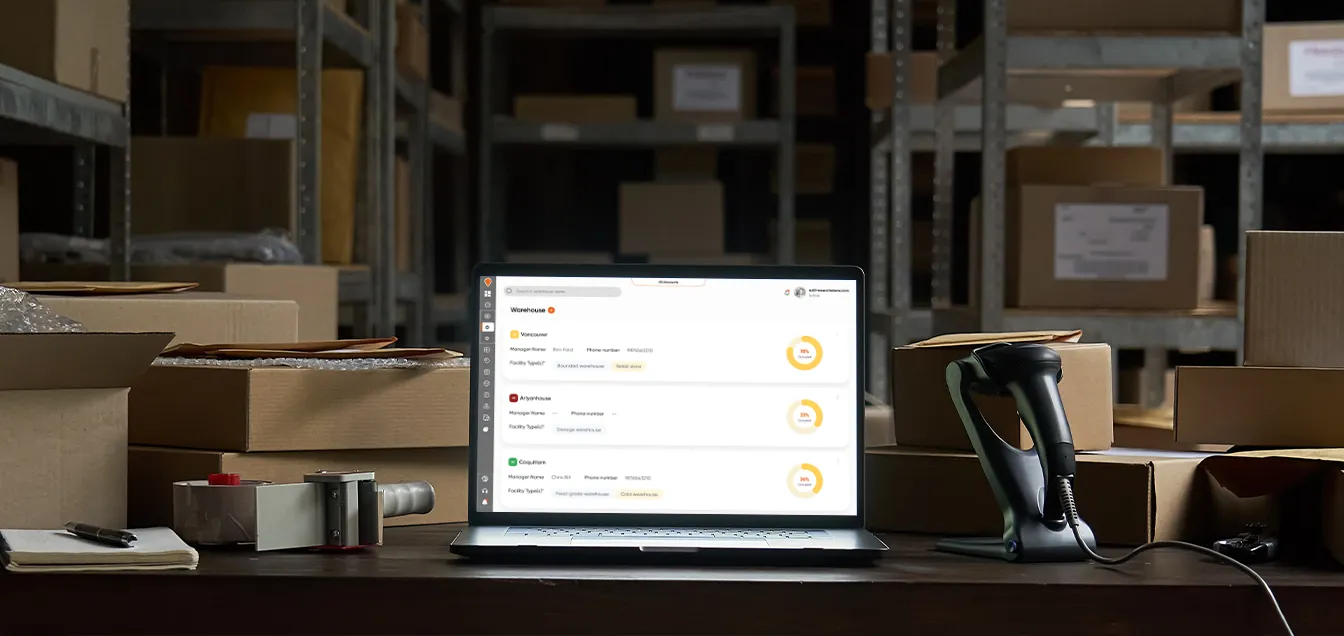

The rise of high-tech fulfillment solutions has transformed the way businesses handle order management and shipping logistics. Companies now frequently use smart warehouses equipped with automated systems to fulfill orders more efficiently. These systems often incorporate technologies like barcoding and RFID (Radio-Frequency Identification) for real-time inventory tracking. One major retailer that implemented a sophisticated logistics system with automation in their sorting centers reported an impressive 50% increase in processing speed while also significantly reducing labor costs. This transformation is precisely why many businesses are now inclined to invest in next-generation distribution technologies.

The Benefits of Cutting-Edge Fulfillment Solutions

When exploring innovative fulfillment options, one cannot overlook the significance of improved analytical capabilities. With access to real-time data analytics, businesses can easily monitor their supply chain performance. This technology facilitates rapid identification of bottlenecks and inefficiencies, allowing for timely interventions. Furthermore, organizations can leverage data-driven insights to optimize their logistics, reduce delivery times, and ultimately boost customer satisfaction. Businesses employing these advanced solutions have reported customer satisfaction scores improving by up to 20%.

Modern Fulfillment Technology

The landscape of fulfillment is constantly evolving, driven by innovative technological advancements. Companies that harness these solutions can automate various core processes while significantly reducing operational costs. This includes a broad array of tools, from sophisticated shipping software to machine learning algorithms capable of predicting shipping delays. For instance, consider a global marketplace that embraced these advancements; they experienced a remarkable 35% reduction in order processing time. This transformation empowered them to respond more effectively to customer needs, ultimately enhancing their competitive edge in the market.

Fulfillment Automation Technology

Embracing automation in logistics operations is essential for modernizing the fulfillment process. This shift streamlines critical tasks like order picking and packing, reducing the dependence on manual labor and significantly minimizing human error. One fulfillment center, for example, reported an impressive 90% decrease in manual errors and a 60% boost in overall efficiency due to these advancements. Additionally, automation enables businesses to scale their operations without a corresponding rise in costs. By embracing these automated solutions, companies can effectively manage increased order volumes during peak periods while maintaining high service quality.

The Importance of Fulfillment Services in Canada

In recent years, the demand for efficient order processing and delivery solutions in Canada has surged, largely driven by the rapid expansion of e-commerce. Businesses looking to enhance their customer experience can gain a significant competitive advantage by exploring fulfillment services in Canada that utilize cutting-edge fulfillment technology. Providers like DelGate, often recognized as the best 3PL logistics in Canada, have integrated innovative solutions that cater to diverse business needs. Their focus on technology-driven fulfillment ensures timely deliveries while reducing operational costs.

Omnichannel Fulfillment Services

With consumers expecting more from businesses, the integration of omnichannel fulfillment services has become critical. Cutting-edge fulfillment technology supports unifying various sales channels, allowing customers to purchase through multiple platforms while still receiving a consistent experience. A notable example is a popular clothing brand that adopted an omnichannel approach, seamlessly integrating both its online and brick-and-mortar inventories. This strategic move led to a notable sales growth of 25% over the year, underlining the vital role of effective fulfillment technology in driving revenue.

Best Warehouse Management Software for Fulfillment

One crucial element in our discussion of cutting-edge fulfillment technology is identifying the best warehouse management software for fulfillment. This software proves invaluable for tracking inventory levels, coordinating logistics, and ensuring that orders are fulfilled accurately and on time. A logistics company utilizing advanced warehouse management software reported a 50% increase in picking speed and a 30% reduction in shipping errors. These statistics highlight how critical effective software solutions are for businesses looking to leverage the advantages of cutting-edge fulfillment technology.

Top Automated Packaging Solutions

To deliver products to consumers more efficiently, companies are exploring various automated packaging options. Introducing automation in the packing process can greatly decrease material waste and increase packing speed. Studies indicate that businesses adopting these innovative approaches have reduced their packaging time by nearly 40%. This not only improves efficiency but also enhances sustainability, an increasingly important factor for many consumers today. Incorporating Top Automated Packaging Solutions and Order Tracking Technology for Fulfillment allows companies to streamline their operations and provide a better overall customer experience.

Order Tracking Technology for Fulfillment

Beyond the solutions previously mentioned, investing in order tracking technology for fulfillment has become increasingly relevant. This technology enables businesses to keep customers informed about their order status in real time. Studies have shown that businesses implementing effective order tracking have experienced significant increases in customer satisfaction rates.

Conclusion

As businesses strive to meet the growing expectations of consumers, incorporating cutting-edge fulfillment technology has shifted from being optional to essential. Companies that proactively adopt these modern practices can significantly boost their operational efficiency and deliver outstanding customer experiences. Whether leveraging advanced logistics strategies or implementing RFID technology, the future looks bright for those ready to innovate in the realm of supply chain management.

FAQs

- What is cutting-edge fulfillment technology?

Cutting-edge fulfillment technology refers to advanced tools and solutions aimed at enhancing order fulfillment processes and supply chain management. - How can advanced fulfillment solutions benefit my business?

They can optimize your processes, minimize mistakes, and enhance overall productivity, resulting in increased customer satisfaction. - What advantages does automation in the fulfillment process offer?

It greatly minimizes human errors, accelerates order processing, and enables businesses to grow operations without a corresponding rise in costs. - Why should businesses look into fulfillment options in Canada?

As the e-commerce landscape continues to expand, efficient fulfillment solutions can ensure timely deliveries and help lower operational expenses. - What are some effective solutions for order tracking technology in fulfillment?

Employing comprehensive order tracking technology for fulfillment keeps customers informed and enhances their overall experience.